Control Systems Integration Specialist

April 24, 2023

Job Location: McKinney, Texas | Anna, Texas | Virtual Remote

Industry & Focus: Water & Wastewater Engineering | Equipment Design & Manufacturing

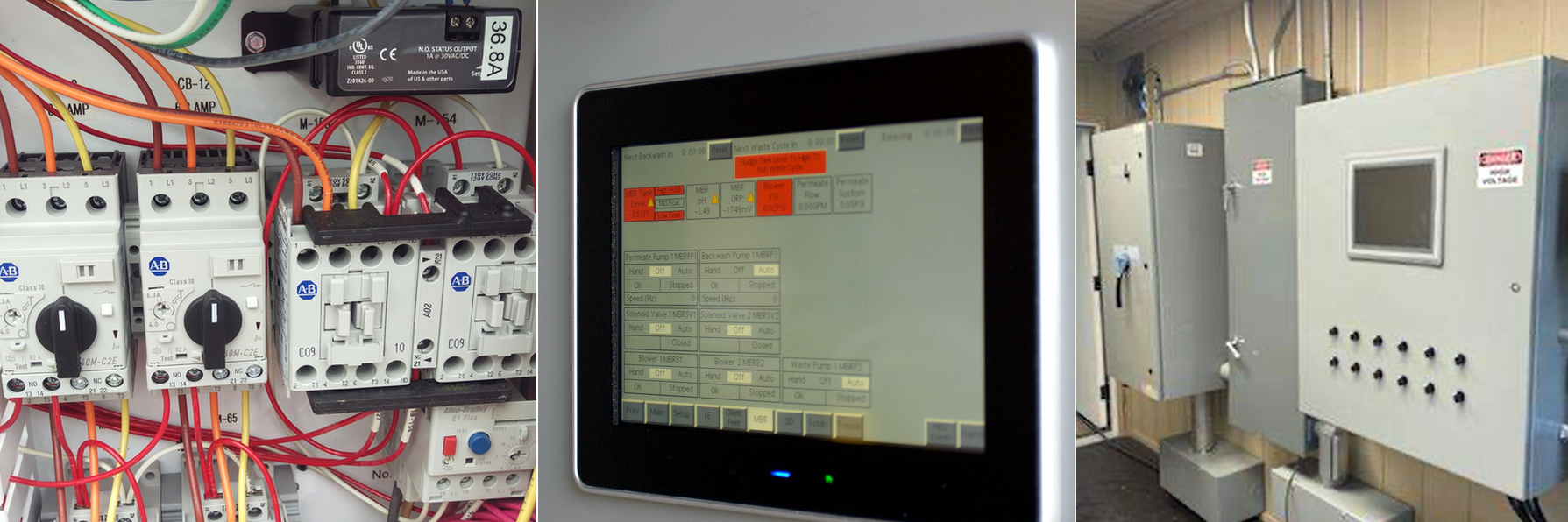

Modular Water Systems (MWS) seeks a self-motivated, intellectually curious individual with a passion for control panel design, systems integration, automation, and PLC/HMI programming that will support MWS’s rapidly growing water equipment business. This full-time position will involve working in a team environment where you will collaborate with an experienced engineering and manufacturing team to design and fabricate custom water and wastewater treatment systems for commercial, municipal, and industrial customers. MWS’s advanced water and wastewater treatment products reflect a combination of sequential sub-unit treatment processes that are integrated into fully functional systems that operate autonomously. See Duties & Qualifications Below

Corporate Background

Modular Water Systems is an engineered solutions provider servicing the North American water and wastewater industry. Its primary focus is the development of packaged water & waste water infrastructure solutions that service the small flow and decentralized water sector. Our wastewater product lines utilize heavy plastic manufacturing (extrusion & winding, rotomolding, injection molding, and press molding) to produce a variety of water infrastructure solutions. In addition to heavy plastics, we also promote and deliver a variety of advanced water and wastewater treatment solutions that address a variety of common to highly unique project requirements.

Modular Water Systems is poised for rapid growth in the water industry. Our engineered products reflect next generation water infrastructure solutions that are paradigm changing and compelling respective to ease of manufacture, first capital cost, life cycle operational costs, durability, and sustainability. The company is driving change within the wastewater infrastructure world and is challenging archaic design practices and obsolete systems that haven’t evolved in more than 75 years. With the growing adoption of our products and technical concepts, it is understood that Modular Water Systems must continually expand its internal engineering capabilities relative to innovation, concept development, product design, final engineering, material science, FEA design, manufacturing engineering, systems integration design, autonomous operations (using emerging AI systems), biological engineering, and biosystems design. To learn more about Modular Water Systems, please refer to the Products section of this website.

Job Duty Description

The Control Systems Integration Specialist will be part of the MWS Engineering Team, responsible for the successful support and on-time completion of water treatment system design and fabrication with an emphasis on the System Integration and PLC Programming associated with the MWS’s equipment packages. The Control Systems Integration Specialist will work closely with Project Engineers and Production Managers to develop the schematics and material bills required for standardized Manufacturing and Customized Production Orders.

The Control Systems Integration Specialist is responsible for and or familiar with the successful execution of all tasks related to electrical design and schematic drafting of a water equipment project. These include power distribution, system control schematics, hardware selection, panel layout, field wiring schematics, conduit and wire sizing selections, and overall adherence to customer and governing agency specifications. The Control Systems Integration Specialist will, in most cases, work closely with a team of equipment designers and fabrication managers in a collaborative design and manufacturing setting. The following generally reflect the typical daily job duties the Controls System Integration Specialist will perform:

- Full-Time Employee working a typical 40-hour work week with occasional overtime

- Serve as part of the MWS Engineering Team working for the Chief Engineer and Engineering Manager

- Work collaboratively with the Engineering and Manufacturing Teams

- Review Process & Instrumentation Diagram drawings prepared by Senior Process Engineers as related to complex water and wastewater treatment systems.

- Review and Utilize Input & Output Schematics complemented by detailed written Functional Process of Operation documentation

- Develop PLC and HMI Control Programs for MWS products and equipment packages. Programming will be “blank sheet” meaning the work will start from initial concept and will evolve over time to reflect standardized programs with common/modular sub-routines. PLC & HMI programming will evolve and expand over time to reflect continued product development and improved system functionality and end user experience.

- Develop written documentation detailing PLC & HMI programming functions for use in Operation & Maintenance Manuals.

- Assist with developing AV Tutorials for End-Users. Tutorials to be systematically developed and categorized for easy End-User access, understanding, and utilization.

- Assist with developing a standardized remote monitoring, alarming, and control system that will allow MWS to effectively support customers during start-up and typical warranty phase.

- Assist with Troubleshooting and Customer Support related to delivered equipment.

- Assist MWS Field Technicians/Start-Up Specialists with remote or on-site controls commissioning.

- This Job Role will evolve over time and provide a very strong opportunity for career advancement.

Skills & Qualifications

- 2+ years of PLC & HMI programming experience

- Must demonstrate proven experience with P&ID and I-O Documentation.

- Familiarity with Allen Bradley, Siemens, ABB, OMRON, Mistubishi, and similar PLC’s

- Familiarity with NUC componentry and use in Industrial PLC applications considered a plus

- Familiarity with Allen Bradley, Red Lion, Siemens, Maple Systems, and similar HMI’s

- Familiarity with common PLC & HMI software

- Previous App Development considered a huge plus

- Previous experience developing new control system software

- Ability to troubleshoot electrical, software, and control systems

- Able to travel to customer sites as needed

- Must be capable of working independently for days at a time on dedicated tasks and project directives.

- Must have strong verbal and written communication skills.

- Must be capable of occasional travel and working in remote locations assisting with equipment commissioning and start-up

- Prefer individuals who are intellectually curious and have natural technical aptitudes and capabilities.

- Prefer individuals desiring to develop PLC programming skills to complement existing electrical designer skills.

Compensation & Benefits

- Compensation Range (base): commensurate with experience and labor market status

- Corporate Quarterly Bonus Program/Individual Merit Bonus Program

- Health & Life Insurance

- Paid Vacation & Sick Time

- Paid Holidays

- Corporate Stock Options

- This job will offer a tremendous opportunity for professional growth with associated potential financial rewards.